Media Release

Ad Hoc announcement pursuant to Art. 53 LR

Whether standard or special solutions, whether as part of a larger system or as a complete module - with its products and services, VAT supports groundbreaking worldwide research work with reliable high-precision valve technology. An excellent example of this is a current cooperation with the Paihau-Robinson Research Institute in New Zealand, which involves novel electric propulsion systems for spacecraft.

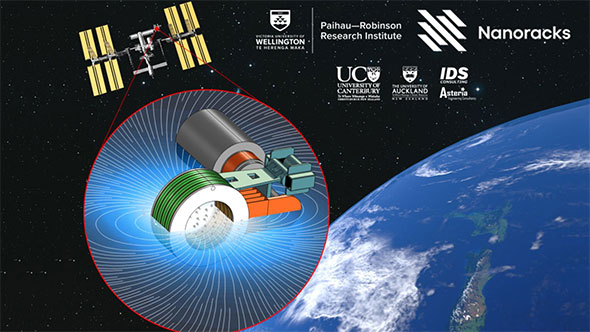

Novel HTS magnet and flux pump technology will soon be tested on the International Space Station (ISS). This same magnet system technology is being incorporated into a type of plasma-rocket called an applied-field magneto-plasmadynamic (AFMPD) thruster that can be used to propel large spacecraft.

Source: Victoria University of Wellington

Significant increase in performance

At the Paihau-Robinson Research Institute, high-temperature superconductivity (HTS) is being intensively researched. The Paihau-Robinson researchers are now making their in-depth HTS knowledge available for space applications, because HTS technology could be a valuable ingredient when it comes to significantly enhancing the performance and flexibility of so-called Applied Field Magneto-Plasmadynamic Thrusters (AFMPD).

To be able to investigate the effect of HTS magnets on the performance of AFMPD propulsion in detail, the Paihau-Robinson Research Institute has set up a space simulation chamber in collaboration with Australian scientific vacuum solution specialist, Scitek. A prototype of the thruster is being developed in the laboratory, with the HTS magnet part of the thruster to be taken to the International Space Station (ISS) and put through its paces in the vacuum of space.

High pumping capacity with steady gas flow

To be able to generate the required working pressure of about 10-7 mbar at an Argon gas flow of 100 sccm in the vacuum chamber, enormously high pumping rates of about 50,000 L/s are needed. This requires, among other things, a large roots pump, powerful turbomolecular pumps, and a 4,200 L/s cryogenic pump – but also special Meissner traps designed to directly pump the Argon gas from the plasma. For these Meissner traps to perform well, the residual moisture in the chamber must be minimized. This is one of the many reasons why Scitek trusts in reliable VAT high-precision valves, such as the VAT 11.1, 12.1, and 14.0 series gate valve and 24.4 series angle valves, for the vacuum components and their control.